Floating Offshore Wind

Toward the realization of decarbonized society

MODEC is developing projects that will enable it to participate in the floating offshore wind power generation market.

Offshore wind power generation systems can be divided into two types: land-based and floating. Floating systems are expected to experience greater market growth as they offer greater wind energy potential and they can be deployed further offshore in locations where water depths do not permit the installation of bottom-fixed systems. MODEC is therefore committed to providing offshore wind power generation systems that utilize floating/mooring technologies developed over many long years of experience in the oil & gas industry with floating production systems.

TLP & Semi-submersible

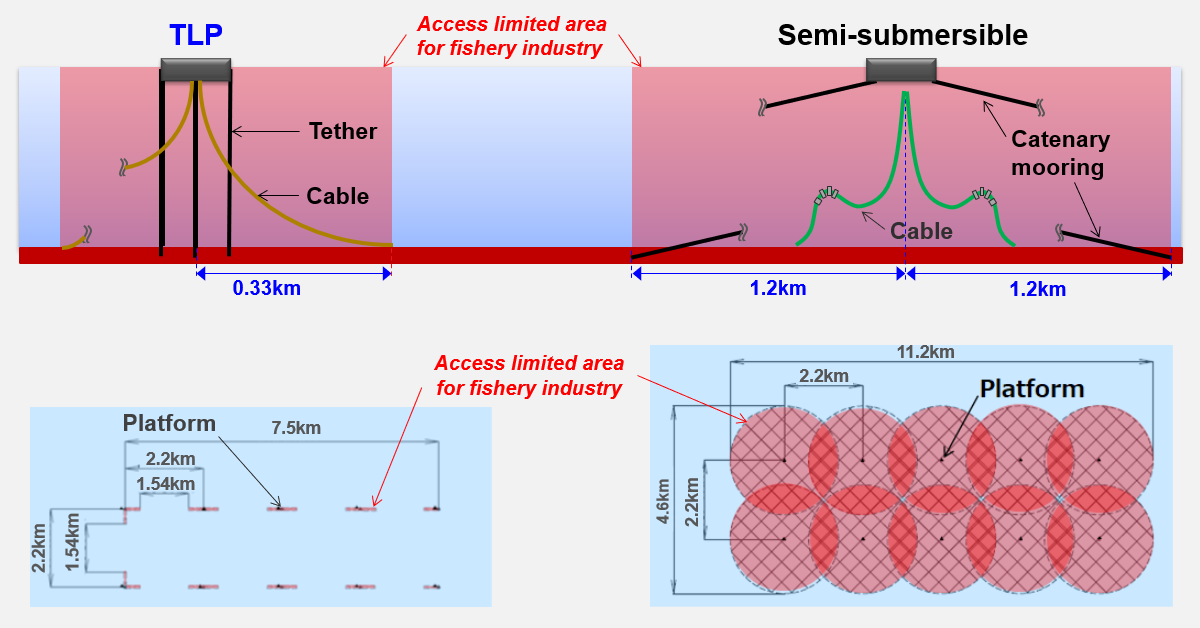

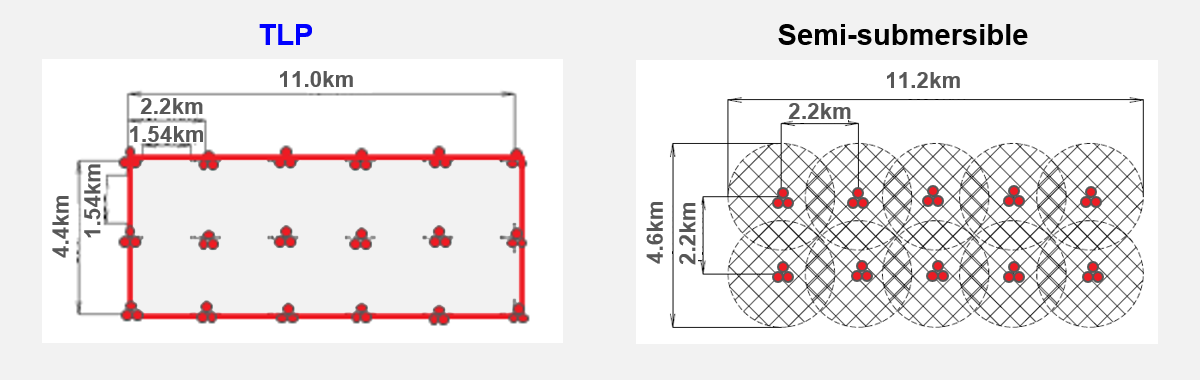

Tension Leg Platforms (TLPs) and Semi-Submersible platforms are two viable options for supporting 10 MW or larger turbines, which are expected to increase in size in the future. We propose an appropriate platform based on the marine conditions of the mooring site, along with the intensions of the company and the local community. TLPs, using tethers, offer the outstanding stability of floating systems with a minimal mooring footprint. The spread mooring used for Semi-Submersible platforms, on the other hand, is more practical for mooring locations where the seabed geology is not suitable for driving in TLP foundation piles.

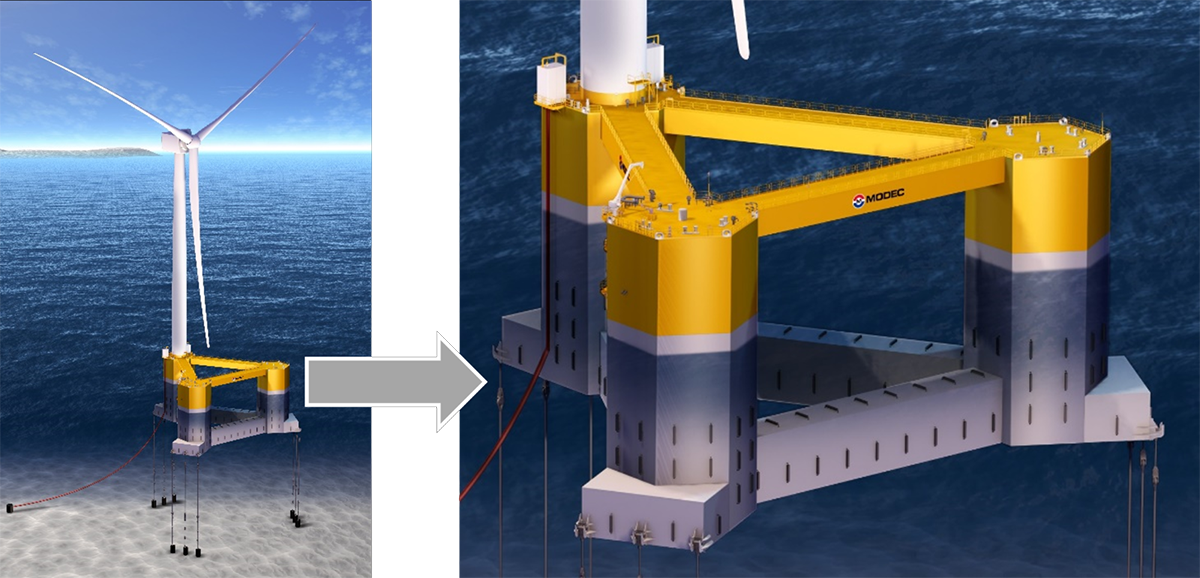

Both TLPs and Semi-Submersible systems have the same basic floating structure of three columns connected by upper and lower box girders and a wind turbine mounted directly on top of one column.

The lower box girders act as both pontoons and strength members, providing sufficient buoyancy for the structure to be undocked from the shipbuilding dock after the wind turbine has been installed, or to be outfitted with a wind turbine in shallow piers less than 10 m deep. This reduces the restrictions on the docks and piers that can be used, which means that on-site installation costs are likely to be lower than installing a wind turbine on a floating system at sea.

Another feature built into this approach is the ability to install the wind turbine at the quayside and tow the platform to the site for installation. If the turbine needs maintenance, this can be done offshore, or the platform can be disconnected and towed back to the quay for turbine maintenance.

TLP's small footprint

The great advantage of TLP is its small footprint. The tension leg mooring lines, which can reduce the occupied area under the sea to approximately 1/1,000 of other mooring systems (for example, in 100m water depth), allow more platforms to be installed within the same size of wind farm.

TLP is also expected to be more socially acceptable than other mooring systems because its small footprint results in less impact on existing businesses such as fishing and shipping.

Column

MODEC's latest model of TLP has three hexangonal columns, produced by putting flat boards together.

Green Innovation Fund

MODEC, together with JERA Co., Inc. (“JERA”), Toyo Construction Co., Ltd. ("Toyo Construction") and Furukawa Electric Industry Co., Ltd. (“Furukawa Electric"), is pursuing the project to develop TLP floating offshore wind turbines.

In 2020, the four companies submitted their proposal for the public offering of Research and Development for Technology to reduce Capital Expenditure (CAPEX) and Operating Expense (OPEX) of Floating Offshore Wind Turbines, which was officially adopted by New Energy and Industrial Technology Development Organization (“NEDO”), and carried out the research and development for two years until March 2022, by assigning TLP including mooring system to MODEC, mooring foundation design and offshore construction to Toyo Construction, and subsea power transmission system to Furukawa Electric.

In 2022, their joint grant application for a project to develop cost-reducing technology for TLP floating offshore wind turbines was accepted by the Green Innovation Fund Program of NEDO, and they have been jointly conducting component technology development for about two years. In addition to conducting simulations and demonstrations of component technologies previously studied by each company, the four are considering supply chains for mass production and cost reduction, with the aim of realizing commercial projects following power generation demonstration.

Related Links

- August 19, 2022 Launch of Survey off Ishikari Bay, Hokkaido, in Preparation for Verification Testing of Power Generation Using TLP Floating Offshore Wind Turbines

- January 21, 2022 Project to Develop Cost-Reducing Technology for TLP Floating Offshore Wind Turbines Accepted by the Green Innovation Fund

- October 30, 2020 Launch of Research and Development to reduce Cost of Floating Offshore Wind Turbines