HSSE

Occupational Safety & Health and Environmental Initiatives

To achieve sustainable development and contribute to society, MODEC understands protecting people which includes our employees, business partners’, local communities’ where MODEC involves and as well as of our stakeholders’ and interest parties for their health and safety, our business and assets, and environment of the planet, we aim to foster a culture of safety and achieve zero accidents.

Management System

To prevent any accidents, loss, or environmental pollution and/or minimize its escalation even if it may occur, MODEC identifies potential sources of danger that could lead to accidents and thoroughly assesses their risks (the probability and frequency of occurrence, as well as the extent/severity of damage or loss). Based on this assessment, various preventive and control measures are established within the HSSE (Occupational Health and Safety, Security, and Environment) Management System (HSSE-MS) that oversees the entire MODEC Group. This system ensures the management of all business activities, including those of affiliated companies, partners, and stakeholders.

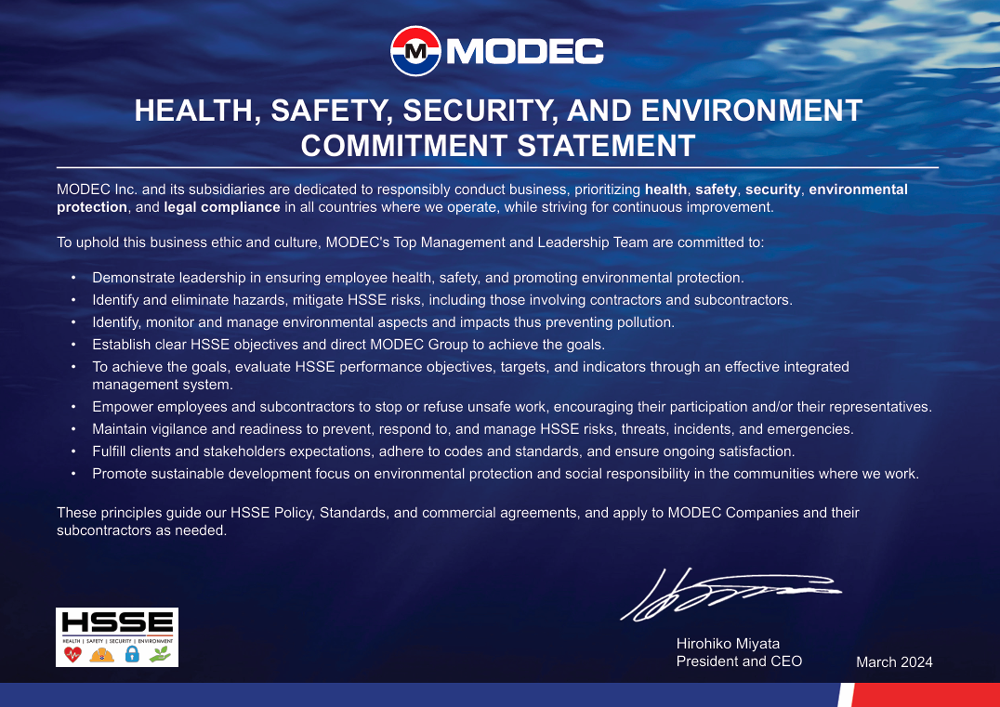

HSSE Commitment

The HSSE Commitment is the highest-level MODEC HSSE Management System document which expresses MODEC’s strong wills towards HSSE. Under the HSSE Commitment, the Group HSSE Policies and Standards are set as second level of MODEC HSSE-MS for all business units/functions, which covers international regulations/statutory, international code and standards, and the standards set by the oil and gas industry (IOGP), as a common regulation. In addition, each business units/functions, vessels, and EPC sites will establish and implement specific business/working procedures reflecting and complying with the requirements by the local unique statutory/regulatory to the country or region in which they are located, as well as the requirements of customers.

CARE Program and Safety Culture

MODEC does not limit HSSE to mere compliance and regulations. It has established the Cultural Awareness Resides in Everyone (CARE) Program, applying to all employees and executives. This behavior-based safety program, focused on human factors, aims to foster and further develop a safety culture unique to MODEC.

Features of MODEC’s HSSE and CARE Program

MODEC's HSSE and CARE Program have the following four major features:

- Stop Work Authority: Any employee may immediately order a work stop if they witness unsafe behavior or conditions, ensuring MODEC does not tolerate any unsafe behavior or conditions.

- CARE Card: A tool that allows all employees to easily report unsafe conditions or issues that need improvement, thereby enhancing safety.

- CARE Survey: A regularly diagnosis of the level of safety culture, which shares weaknesses and strengths and areas that need improvement with all employees, thus aiding in the review of safety behavior and fostering a safety culture.

- Life Saving Rules: A set of rules identifying particularly dangerous tasks, used to alert all employees through training and materials, to ensure awareness and safety.

MODEC Group HSSE Executive Committee

MODEC group organizes "MODEC Group HSSE Executive Committee" supervising and monitoring activities of entire Group's occupational health & safety, security and environment. The committee is chaired by Global HSSE Lead and consists of CEO of MODEC, INC. , heads of each business units and Chief Compliance Officer.

HSSE Committee

Each entity organizes a local HSSE Committee. Tokyo headquarter has in place "HSSE committee" in the purpose of following aims:

- 1Ensuring the health and safety of our employees, the protection of the environment

- 2Set HSSE performance objectives, measure results, assess and continually improve processes through the effective integrated management system

- 3Empower and support all employees and subcontractors with the right to STOP WORK or refuse to work in situations where conditions or practices are deemed unsafe

- 4Contribute to sustainable development through environmental protection

- 5Other important matters recognized as necessary for safety, health and environment protection

General Occupational Health & Safety and Environment Manager (executive officer in charge of HSSE) chairs HSSE Committee, which consist of Occupational physician, Health Supervisor (designated by law) and Representative of workers (appointed by half of committee members in the union) .

HSSE Statistics

| Year to Year | |||

|---|---|---|---|

| 2024 | 2023 | 2022 | |

| Exposure Hours | |||

| Employee | 13,387,734 | 12,854,508 | 12,026,103 |

| Contractor | 40,467,742 | 30,843,267 | 51,978,567 |

| Total Exposure hours | 53,855,476 | 43,697,775 | 64,004,670 |

| Fatalities (work related) | |||

| Employee | 0 | 0 | 0 |

| Contractor | 0 | 0 | 0 |

| Total Fatalities | 0 | 0 | 0 |

| Injuries | |||

| Lost Time Injury Frequency Rate Employee | 0.37 | 0.54 | 0.23 |

| Lost Time Injury Frequency Rate Contractor | 0.17 | 0.23 | 0.08 |

| Lost Time Injury Frequency Rate (Total) | 0.22 | 0.32 | 0.11 |

| Total Recordable Incident Frequency Rate Employee | 1.12 | 0.86 | 0.78 |

| Total Recordable Incident Frequency Rate Contractor | 0.39 | 0.88 | 0.41 |

| Total Recordable Incident Frequency Rate (Total) | 0.58 | 0.87 | 0.48 |

| Occupational illness | |||

| Employee | 4 | 9 | 13 |

| Contractor | 2 | 1 | 3 |

| Total Recordable Occupational Illness Frequency Rate (employees only) |

0.30 | 0.70 | 1.08 |

| Security | |||

| Work-related security incidents | 9 | 6 | 6 |

| Work-related security incident resulting in physical harm to employees (number) |

0 | 1 | 0 |

LTIF= Number of Lost Time Injuries x 1,000,000/ Manhours Worked

TRIR=Total number of Recordables x 1,000,000/ Manhour Worked

Monitoring of Process Safety Events (PSEs)

MODEC actively monitors Process Safety Events (PSEs) to promote continuous improvement in operational safety and reliability. In accordance with API Recommended Practice 754, events are classified as Tier 1 or Tier 2 based on their severity and potential impact.

| Year to Year | |||

|---|---|---|---|

| PSE | 2024 | 2023 | 2022 |

| Tier 1 incidents (number) | 2 | 6 | 3 |

| Tier 2 incidents (number) | 8 | 14 | 4 |

A Tier 1 PSE is defined as an unplanned or uncontrolled Loss of Primary Containment (LOPC) of any material, including non-toxic and non-flammable materials from a process (e.g., steam, hot water, nitrogen, compressed CO2 or compressed air), or that results in one or more consequences, such as injuries or financial damages, with defined thresholds by API RP 754.

Tier 2 PSE represent occurrences of lower consequence, which highlight opportunities for system enhancement.