Mooring Systems

You can count on us at any water depth or in any type of weather to safely transfer your produced oil and gas. Whether in iceberg-prone North Atlantic or the deep waters of Brazil or West Africa, our experts provide reliable and turnkey external and internal (disconnectable and permanent) turrets, spread mooring, and tower yoke systems for FLNG and FPSO vessels.

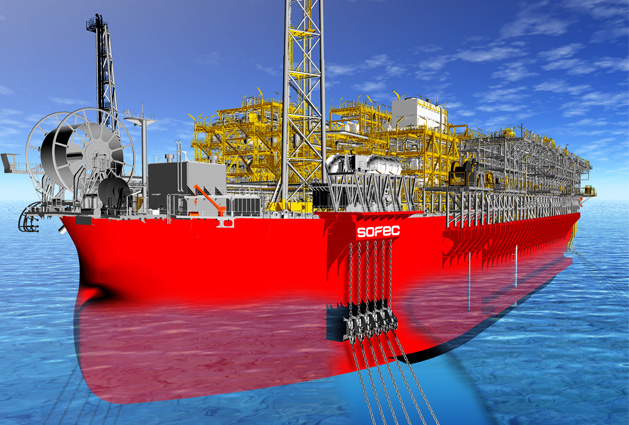

SOFEC® External Turret

Our external turret systems have matured to embrace the most advanced technology, including swivel stacks to accommodate higher subsea production pressures and multiple risers for transfer of produced oil, gas, and water injection, as well as electricity, hydraulics, and fiber optics from subsea to the vessel or vice versa.

Product Features

- Industry-leading, proven technology

- Accommodates many risers in the full range of water depths

- Permits vessels to weathervane 360° in moderate to extreme sea conditions

- Economical and fast to produce

- Frees up vessel processing and storage space

- Flexibility to mount at either the bow or stern of converted tankers or newly built vessels

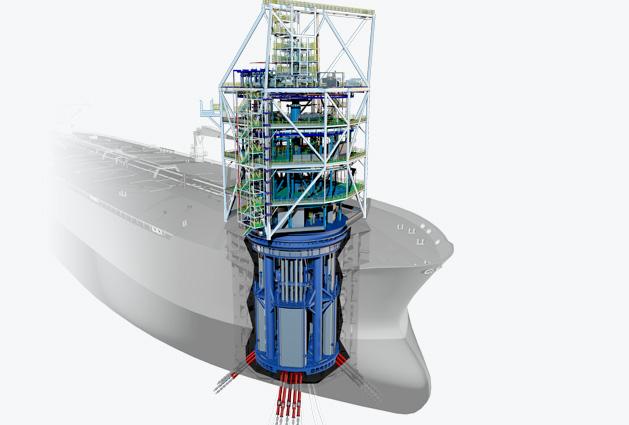

SOFEC® Internal Disconnectable Turret

Internal disconnectable turret enables vessels to disconnect and sail away to avoid typhoons, hurricanes, and icebergs in remote, deep water, and other challenging environments. Ships return to normal production operations with a quick, reliable reconnect sequence. The design adapts to a wide range of water depths.

Product Features

- Disconnects to avoid typhoons, hurricanes and icebergs

- Returns to normal production operations with a reliable quick and easy reconnect sequence

- Permits vessels to weathervane 360° thereby reducing mooring loads while connected

- Enhanced mooring load capacities

- Adapts to a wide range of water depths from 60 to more than 3,000 meters

SOFEC® Internal Permanent Turret

FPSO and FSO vessels operate further offshore, in deeper waters, and in harsher environments. Internal permanent turret mooring systems enable vessels to remain securely operational despite harsh conditions.Suitable for both existing and new-built vessels, the permanent internal turret offers greater mooring and fluid transfer capabilities, accommodating 100 or more risers and adapting to a wide range of water depths in the world’s harshest offshore environments.

Product Features

- Vessels remain secure in the most demanding design conditions

- Enhanced mooring load capacities

- Allows vessels to weathervane 360° in normal and severe conditions

- Adapts to a wide range of water depths from 60 meters to more than 3,000 meters

- Accommodates 100 or more risers

SOFEC® Spread Mooring

Spread mooring systems use four groupings of anchor legs arranged symmetrically. The anchor legs attach to the bow and stern on the port and starboard to secure the vessel in place with a fixed heading.

Product Features

- Uses traditional shipboard mooring equipment

- Does not require turret structure, bearing, or swivels

- Accepts all types of anchor leg configurations

- Easily accommodates large numbers of risers and umbilicals

SOFEC® Tower Yoke

Tower yoke systems are cost-effective, reliable solutions for permanently mooring FPSO and FSO vessels in shallow water. The yoke system links the vessel to a fixed tower outfitted with a mechanical turntable, which enables the vessel to weathervane freely around the tower. The yoke allows the vessel to pitch and roll, sway and yaw, and heave and surge without inducing unacceptable loads on the mooring links.

Product Features

- Economical and reliable for vessels in shallower waters

- Tower yoke system links a vessel to a fixed tower

- Flexibility to mount on the bow or the stern of a converted tanker or new-built vessel

- Permits vessel to weathervane 360° thereby keeping environmental loads manageable

- The yoke, connected to the turntable with specially designed joints, allows the vessel to move with all six degrees of freedom

- A large, water-filled ballast tank on the yoke minimizes vessel excursions

- Fluid travels via flexible hoses between the tower and the vessel

- Ample deck space is available for auxiliary equipment

- Easily accessible with walkways to access the tower