Offshore Research & Development

While our client’s needs may evolve, our goal remains the same – deliver reliable solutions and improved operations for the offshore industry.

Our research and product development initiatives include improved structural and mechanical systems, enhanced process design, and expert materials engineering; each supported by computational fluid dynamics, sophisticated wind tunnel and wave tank testing, and numerical analyses. Our results lead to innovative mooring and fluid transfer solutions that yield improved safety and highly reliable technologies for our clients.

Research & Product Development

Our highly educated and experienced team develops new and customized technologies that enable offshore vessels to operate in higher pressures, various water depths and harsher environments. Based on field data, as well as advancements in technology and materials, we continuously improve our products at our research facilities in Houston.

Our Asset Integrity team provides condition monitoring and advanced analytics for our mooring system technologies to support clients with the alternative energy transition.

Guided by open communication, collaboration, and a strong client focus, we assist our clients with component development and improvement

- Dual-axis chain support assemblies

- Chain support deployment system for internal turrets

- Replaceable roller bearing technology

- Testing of synthetic bearing materials

- Integration of steel risers to internal and external turrets

- Extension of swivel capabilities (temperature and pressure)

- Testing of swivel seal materials and designs

- Implementation of high voltage swivels and power circuits on single point mooring systems

- Robust anchor leg monitoring systems

- Turret monitoring systems and associated digitalization efforts for condition monitoring

- CFD applied to fluid-structure interaction

- Various component and system standardization efforts

Mooring Systems

Design and supply of a Marine Terminals on a fast track basis to the turnkey mooring development for a sophisticated Floating Storage and Offloading (FPSO) vessel, we has the technology, experience, and resources to get the job done on time and on budget.

We are continually engaged in research involving new and improved tanker mooring systems and associated components. SPMs encompass a wide array of systems which moor vessels in the open sea. Turret moorings permit vessels to “weathervane” 360 degrees, allowing continued operations in extreme sea conditions.

Using model test data in conjunction with computer analyses to optimize system designs, we leads the industry in producing the highest quality systems at the lowest possible cost. Research and development efforts include development of new SPMs, both permanent and disconnectable, for floating storage and processing in both shallow and deep water, for cyclone prone areas and for service in ice congested Arctic waters. We continually verifies computer models against model test data to ensure the ability to provide our clients with the most accurate load and motion analysis. In addition, we are developing high pressure swivel systems to meet the demands of deep water production.

Types and Features:

- Water depths from 19 to over 3,000 meters

External Cantilevered Turrets:

- Mild to moderate environments

- Southeast Asia, West Africa, Middle East, Latin America, Brazil, Australia, New Zealand

Internal Turrets:

- Permanent and Disconnectable systems

- Moderate to harsh environment / deep water applications

- Gulf of Mexico, North Sea, North Atlantic, South China Sea, Brazil, Australia, New Zealand

Asset Integrity Services

Let us manage your single point and spread mooring system assets.

Our experts’ knowledge, coupled with customized inspections, integrity reviews and condition monitoring, offer you a blueprint for operations, maintenance, modifications and life extensions for these systems.

Our Asset Integrity Services team offers

- Inspection support and integrity reviews

- Annual surveys of mooring systems for tower yoke, turrets and CALM buoys by specialized our inspectors

- Inspection programs for third parties (mooring, structure, process equipment)

- Integrity assessments and fit-for-purpose engineering analyses by in-house subject matter experts based on (third-party) inspection reports

Condition monitoring extends the life of your mooring systems and include

- Bearing grease monitoring to detect premature wear in the main and swivel bearings

- Condition monitoring for critical components, such as:

- Station keeping and motions monitoring systems

- Mooring and anchor leg monitoring systems

- Swivel and bearing control systems

- Real-time condition monitoring for component and system status

- Long-term operational performance assessment

- Advanced analytics (digital twin) solutions for predictive maintenance

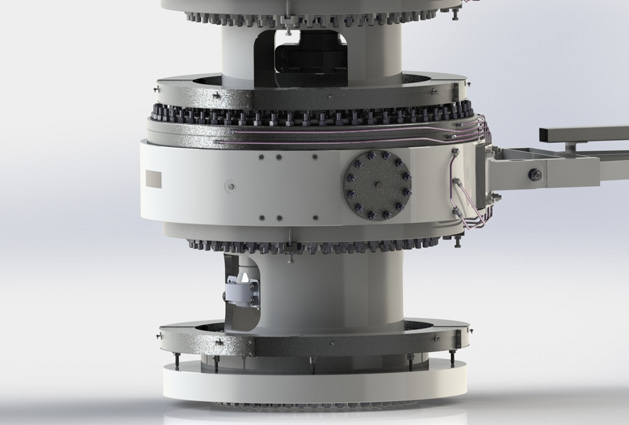

Swivels

Swivel technology is the heart of advanced mooring systems.

Our swivel systems feature complex designs and innovative technology that are proven and cost-effective. From single-product loading and offloading buoy swivels to multi-riser, multi-phase swivel stacks, our dedicated swivel engineers design a custom fluid swivel solution for all single-point mooring systems.

All our swivel engineering, from analysis to testing, is performed in-house.

Marine terminal solutions

For loading and offloading tanker cargo, our buoy swivels transfer large volumes of fluid safely and efficiently with little maintenance. One or more fluids simultaneously move through our buoy swivels. Our technologies include:

- Single-product swivel

- Multi-product swivel

Turret moored solutions

For turret mooring systems, we use a modular approach to combine swivel technologies as well as work with third-party electrical and optical slip rings. The modular approach allows for the swivels to be serviced and seals to be changed out quickly and efficiently. Our swivel technologies include:

- Toroidal swivels

- Utility swivels

- Inline swivels