Research & Development

Explore a Sustainable Future with Innovation

At MODEC, our R&D is where ocean meets innovation. We continually deepen the relationship between the ocean and humanity and pioneer a sustainable future with unwavering curiosity, practical ingenuity, and a frontier spirit.

FPSO Decarbonization

New Floating Solutions

New Mooring Solutions

Lifecycle Value Enhancement

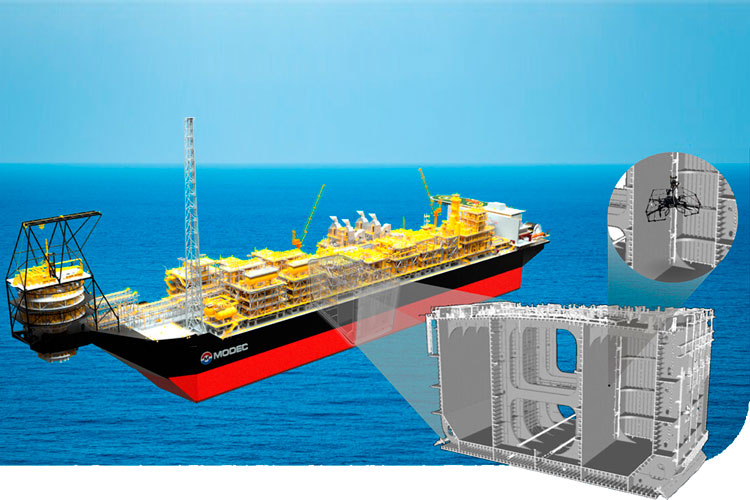

FPSO Decarbonization SOFC

A Solid Oxide Fuel Cell (SOFC) is a type of fuel cell that converts chemical energy directly into electricity using a solid ceramic electrolyte at high temperatures. The high-temperature tolerance also provides fuel flexibility, so SOFCs can use hydrogen, natural gas, methanol, or ammonia. Leveraging the fuel flexibility noted above, SOFCs can utilize associated gas streams common on FPSOs.

MODEC, in collaboration with Norway’s ELD Energy, is developing a SOFC power generation system as a next-generation alternative to gas turbine generators (GTGs) on FPSOs.

We are developing a high-efficiency SOFC power generation system, which targets to achieve more than 60% electrical efficiency under offshore operating conditions, integrated with a compact, low-energy carbon capture (CC) system. SOFC + CC provides a practical pathway to deep decarbonization without compromising uptime.

FPSO Decarbonization Carbon Capture

MODEC has already implemented and operated pre combustion carbon capture on live FPSOs, recovering CO2 from CO2 rich produced gas and reinjecting it to the reservoir together with surplus gas.

Building on this expertise, we are conducting R&D to integrate post combustion carbon capture on FPSOs, targeting exhaust from GTGs and other power generation systems that account for the majority of an FPSO's GHG emissions. MODEC is evaluating multiple post combustion technologies while developing fit for purpose PCCS solutions tailored to FPSO specific constraints, with the goal of reliable, maintainable, and cost effective deployment offshore.

Footprint Reduction Technologies

Offshore facilities face spatial constraints compared to onshore power plants. We are developing solutions to minimize the size of carbon capture systems while maintain efficiency.

Energy-saving PCC Operations

FPSOs require significant thermal energy for crude oil separation. Energy-efficient CO2 separation methods are being developed to enhance overall operational efficiency.

New Floating Solutions FNPP

Global electricity demand is projected to increase by up to threefold by 2050. MODEC considers that offshore floating nuclear power plants (FNPPs) can play a vital role in meeting this increased demand while minimizing GHG emissions to support human flourishing. More broadly, FNPPs provide reliable baseload that complements renewables and helps stabilize grids in coastal and island regions. By leveraging standardized modules and proven offshore execution, they offer a practical, scalable pathway to clean energy addition.

New Floating Solutions LCO2 FSIU

“LCO2 FSIU (Floating Storage and Injection Unit)” would be able to receive LCO2 transported in low pressure condition, store, and inject it into subsea wells at high pressure for permanent sequestration, which eliminates a need for onshore LCO2 receiving plant and pipeline to injection wells.

By serving as an offshore storage and injection hub, the FSIU enables the sequestration of CO2 into qualified reservoirs. By offering large-scale, flexible, and reliable offshore CO2 storage, this solution supports the global transition to low-carbon energy.

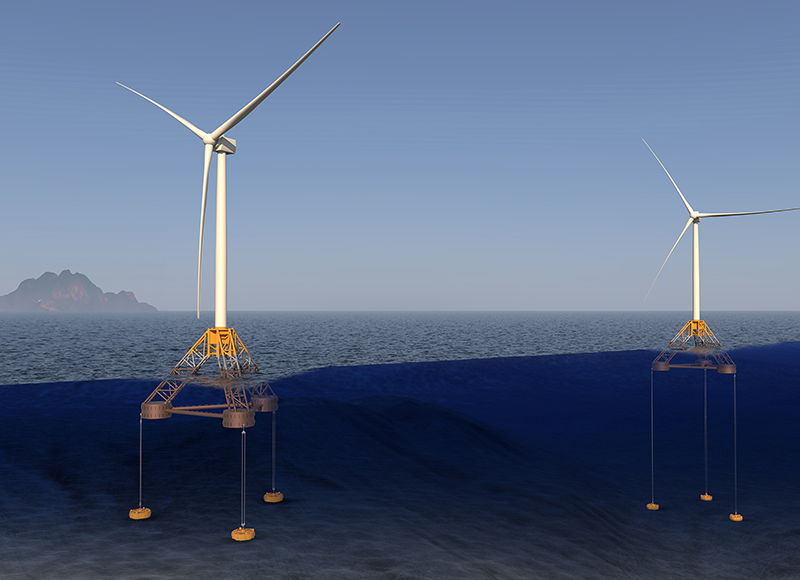

New Floating Solutions FOWT

In realizing FOWTs (Floating Offshore Wind Turbines) in a global energy mix, the cost of electricity is the largest barrier. MODEC, a leading provider of TLP platforms in Oil & Gas, is contributing to the growth of the FOWT industry by applying its proven technology and track record to floating wind.

Our iTLPTM concept is under active development as a solution to minimize LCOE while maximizing energy production at the site, combining low motion, efficient installation, and robust lifecycle performance, including in-situ maintainability.

Building further on this concept, MODEC is also advancing solutions for bottom fixed offshore wind in water depths previously considered impossible for conventional foundations, opening new resource areas for competitive offshore wind.

MODEC Secures AiP for i-TLP™2, an Innovative Offshore Wind Turbine design from ABS

New Floating Solutions Ammonia FPSO

In the energy transition, low carbon fuels such as ammonia are expected to play a some role in decarbonizing power and industry. Anticipating a maturing market, MODEC is developing product concepts to meet emerging demand, including a Low Carbon Ammonia FPSO. This floating solution converts associated gas—often reinjected today—into low carbon ammonia offshore.

Obtained an Approval in Principle (AiP) by ABS for Blue Ammonia FPSO

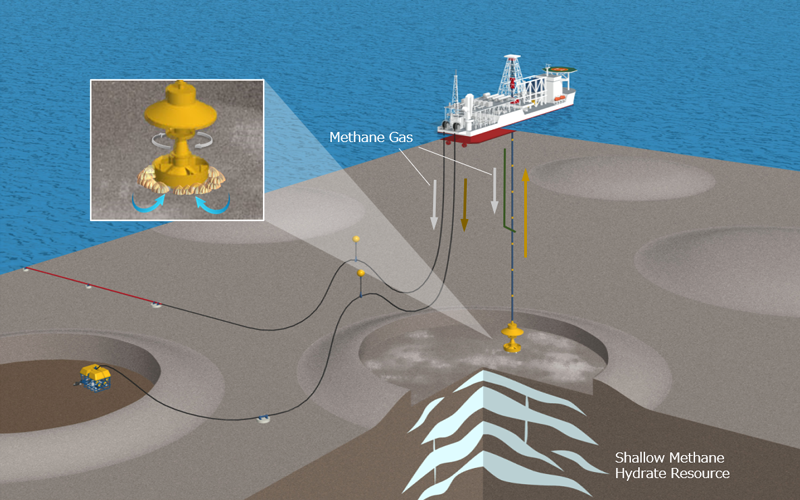

New Floating Solutions Offshore Methane Hydrate

MODEC is contributing to an effort to develop methane hydrates by advancing research and development toward commercial-scale recovery of shallow methane hydrates, building on our proprietary capabilities and operational experience.

New Mooring Solutions Jetty-Less Offshore Terminal for New Energies

The expected rise in demand for alternative energy, the need for offshore charging solutions, and the development of offshore CO₂ injection sites are driving new infrastructure requirements for safe offshore transfer and handling.

Operators need safer, quick-deploy solutions that reduce cost, shoreline exposure, and project execution risk. To meet this demand, MODEC is repurposing proven SOFEC® CALM buoy and Loading Tower technology to enable jetty-less offshore transfer of alternative fuels, power, and CO2. Our R&D program focuses on concept development, technical qualification of critical components for the new application, and system safety assessment. An AiP for the jetty-less ammonia terminal confirms technical readiness.

New Mooring Solutions Submerged Yoke System Development

MODEC is responding to rising demand for shallow-water mooring as FSRU and FLNG projects accelerate. With a long track record in tower yoke systems, including the industry’s first and only disconnectable tower yoke, we are advancing SOFEC® Submerged Yoke Mooring System (SYMS) product line, tailored to specific market needs. R&D and product development program covers concept development, marinization of underwater components, detailed engineering of critical assemblies, and system optimization. The submerged yoke system is offered in both permanent and disconnectable configurations to match project requirements.

Lifecycle Value Enhancement Digital Initiatives

MODEC is advancing a dedicated digital strategy through its spin off, Shape, which delivers three products—Shape Lighthouse, Shape Aura, and Shape Reef—to the market. Driven by internal needs for operational efficiency and decarbonization, we are conducting R&D with Shape to create new digital products that address real challenges in the industry.

In parallel, we are heavily investing in our Digital & Analytics team to strengthen internal execution capabilities—turning data into actionable insights, optimizing workflows, and improving safety, reliability, and cost.

Brazilian technology uses artificial intelligence to improve oil platform safety

Lifecycle Value Enhancement Robotics-assisted Operation

MODEC is advancing R&D to replace hazardous tasks with robots, pursuing operations that are safer and more humane. Beyond safety, robotics help address offshore POB (personnel onboard) constraints, enabling more efficient, reliable execution with fewer people on site.

Drone based tank inspection is one example now in routine use, freeing operators from confined space and work at height risks while achieving competitive costs.

MODEC and Terra Drone Renew Joint R&D Agreement for FPSO Crude Oil Storage Tanks Inspections

World's First Approval from Classification Society for a Drone-based FPSO Hull Thickness Measurement

Lifecycle Value Enhancement CFRP Repair

Suspending production and moving an operating FPSO to a shipyard for repairs results in significant project losses. Even when conducting repairs offshore, any hot work necessitates a shutdown of crude oil production, and there are weight constraints on boarding materials and repair personnel.

With such circumstances requiring the development of a new offshore hull-repair method, MODEC is continuously developing steel repair methods using CFRP (Carbon Fiber Reinforced Plastic) to address hull corrosion offshore without hot work, enabling repairs to be completed by small teams in short timeframes.

The primary purpose of this repair method is to minimize the impact of repair work on production but, because limitation of work site and penalties for suspending production can also be avoided, major benefits can be expected for the project as a whole.